Next Generation Additive Manufacturing uses AI and Enhanced Laser Precision

Breaking News:

Künstliche Intelligenz und Automatisierung: Potenziale und Herausforderungen im Projektmanagement

Stark in die Bildungs-Zukunft: Jetzt für das Future Skills Programm “Starkmacher” bewerben

BasicBox – Briefkastenanlagen günstig und schnell geliefert | KNOBLOCH

Digitale Rückverfolgung im Tierfutter-Großhandel? COSYS zeigt, wie’s geht!

Samstag, Apr. 19, 2025

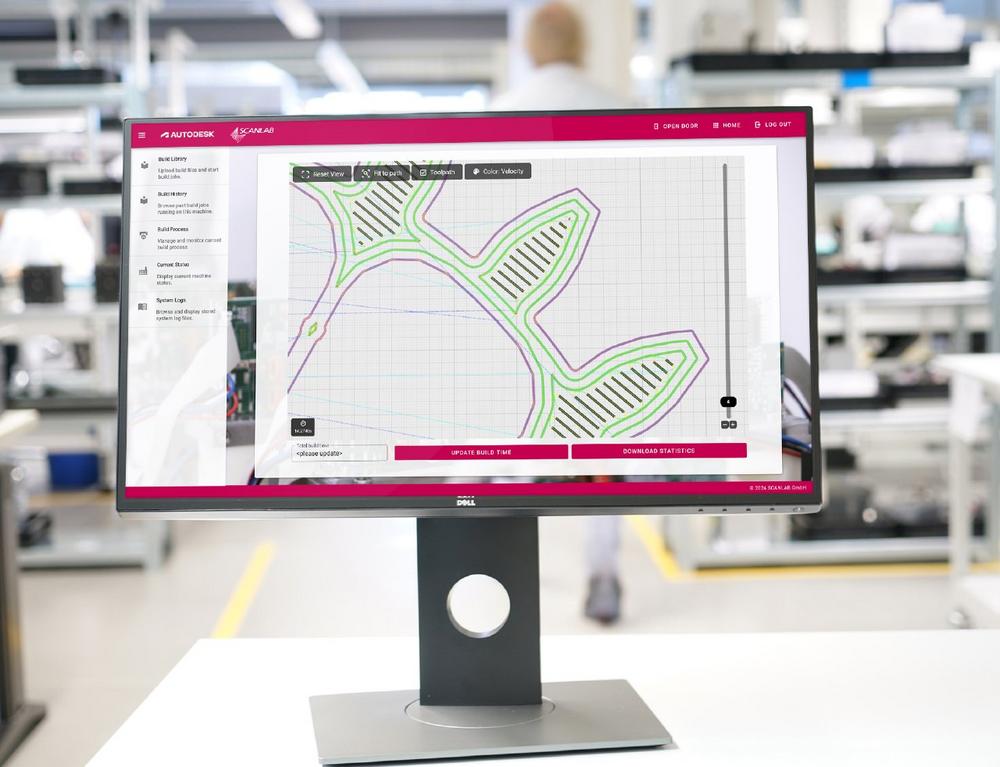

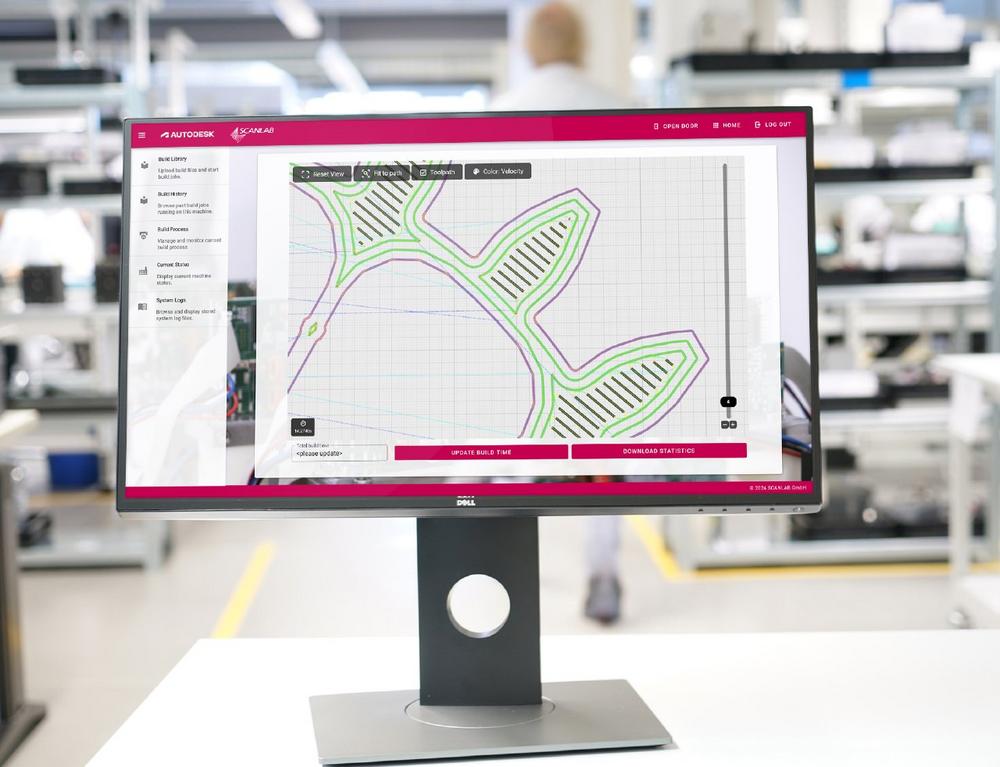

Additive manufacturing (AM) and especially metal AM strives for increasing throughput and less scrap. Data preparation is key to increase productivity and shorten process development times. The control system SCANmotionControl allows process developers to simulate the scan paths of the lasers offline on the PC. As the physical properties of the scan systems are taken into account in the simulation, the paths in the application are executed by the machine exactly as in the simulation: ‚What you simulate is what you get‘.

The combination with the powerful Physics-AI platform AMAIZE enables manufacturers to print thin, complex geometries and engineer advanced thermal profiles with intelligent automation. Customers obtain first-time-right production, better overhangs, superior surface quality, and full transparency over the entire manufacturing process.

“This collaboration reveals the possibilities when cutting-edge laser scan systems and AI work in coordination,” states Dr. Daniel Reitemeyer, Business Development Additive Manufacturing, at SCANLAB. “AMAIZE’s detailed prediction is the ideal match for our advanced SCANmotionControl solution. Our software allows freeform power profiles on a single vector, individually for every vector of a print job. The AI-based point-wise power optimization permits automated process parameter calculation, which is a pre-requisite for advanced scan control on industrial level. The combination offers our customers highest performance and control.”

The software integration is based on the open ‘3MF’ 3D Manufacturing Format, ensuring an immediate scalable deployment for machine builders. Alexander Oster, Technical Chairman of the 3MF Consortium, comments: “For years, the 3MF Consortium has been working on standardizing every step in the additive manufacturing toolchain. The craftsmanship and scalability of the 3MF toolpath extension, combined with 1000 Kelvin’s AI and SCANLAB’s high frequency control precision demonstrate the true power of ecosystem-driven innovation. We are finally witnessing the emergence of high-end geometries printed repeatable, faster, with greater quality, and with machine specific predictive optimization – while taking into account everything down to laser reaction times and the inertia of the scanning mirrors.”

“We’ve developed a physics-based foundational model purpose-built for manufacturing—trained to understand and control the laser-material interaction,” explains Dr. Katharina Eissing, CTO and Co-founder of 1000 Kelvin. “With 100 kHz temporal resolution and power modulation along vectors, our AI doesn’t just predict—it governs the process at the level where material behavior is shaped. Working closely with SCANLAB, we’ve integrated this intelligence directly into the laser path control, bridging software and hardware like never before.

For machine builders and end users, this unlocks a new era: the ability to print highly complex materials and geometries with granular control, computational efficiency, and reproducible results. It’s the missing piece between digital intent and physical reality. And it means that, finally, AI speaks the language of physics in the factory” she concludes.

AMAIZE’s core engine—already powering leading aerospace, defense, and energy manufacturers—together with SCANmotionControl provides machine integrators an easy to use AI-native recipe generation to differentiate on the global stage.

SCANLAB GmbH is a world-leading and independent OEM manufacturer of scanning solutions for deflecting and positioning laser beams in three dimensions. At the company’s headquarters in Puchheim near Munich, around 500 employees strive to ensure continuous innovation and a production capacity of over 40,000 systems every year.

SCANLAB’s high-performance galvanometer scanners, and scan systems stand out from the crowd for their speed and precision, and are widely used in industrial material processing, electronics, food and beverage industries, as well as in biotechnology and medical technology.

Through groundbreaking developments in the fields of electronics, mechanics, optics and software, as well as the highest quality standards, SCANLAB has consistently extended its international technological lead over 35 years.

About 100 Kelvin

Founded in 2021, 1000 Kelvin enables companies using additive manufacturing in production to get qualified parts to market faster at a lower cost. The company’s AMAIZE software is the “AI co-pilot” for engineers, using AI models to predict print issues, perform corrections, and generate print files specific to a machine. With AMAIZE, users get prints right the first time.

SCANLAB GmbH

Siemensstraße 2a

82178 Puchheim

Telefon: +49 (89) 800746-0

Telefax: +49 (89) 800746-199

http://www.scanlab.de/

![]()