Making hygienic food production highly efficient

IFFA, taking place May 3 – 8 at Messe Frankfurt in Germany, is the world’s leading trade fair dedicated to technology for meat and alternative proteins, providing a global platform for food industry innovation. Stäubli Robotics will present live demonstrations and offer expertise on how producers can level up their efficiency and productivity with advanced hygienic robots.

Stäubli Robotics has been at the leading edge of food industry automation for decades, working with partners and customers to develop systems that automate applications from primary processing to secondary packaging and intralogistics, including pick and place, sorting, cutting, deboning, portioning, packaging and palletizing.

Getting food robots right: Hygienic design and beyond

Equipment used in the food industry must meet strict requirements to prevent contamination and protect food safety and quality. Stäubli’s food robots follow European Hygienic Engineering & Design Group (EHEDG) guidelines for hygienic design, which are widely regarded as the gold standard. Stäubli robots epitomize key aspects:

Must-see robot exhibits and demos at IFFA

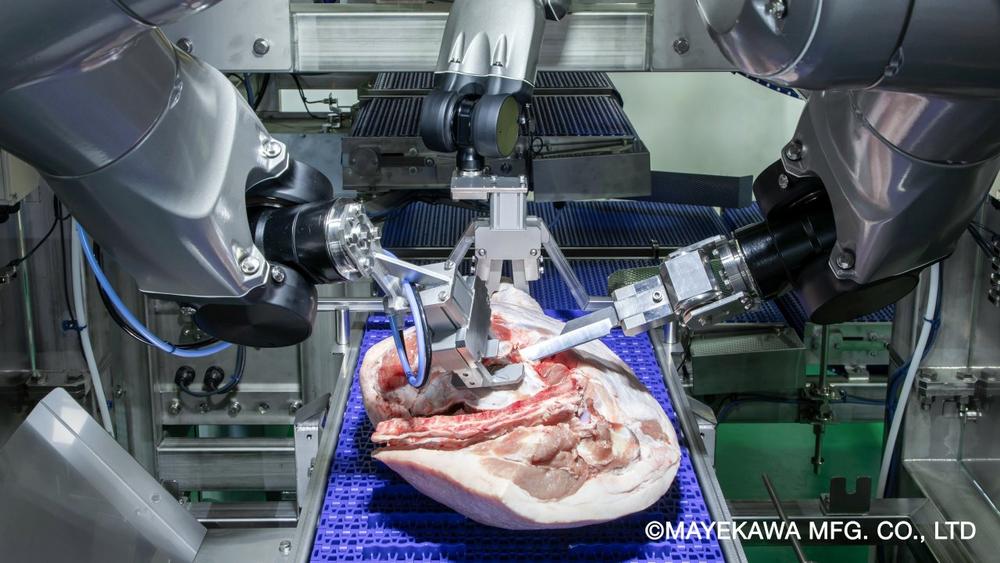

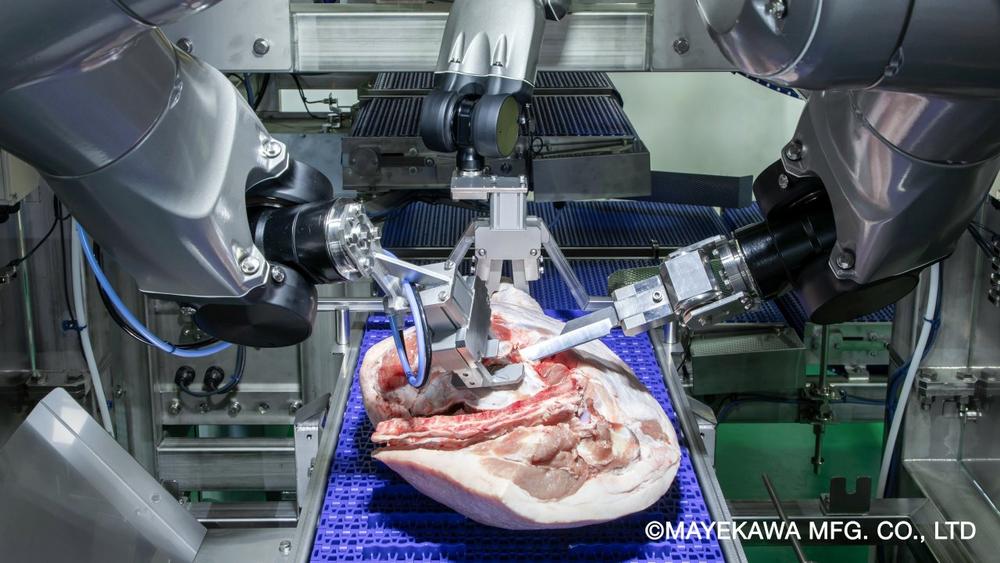

To support the food industry’s complex workflows, Stäubli Robotics offers a comprehensive portfolio of HE (humid environment) robots modified to maintain process reliability in harsh environments. Live demonstrations at IFFA will show how they automate meat processing tasks safely while delivering high efficiency and consistent quality.

One demo will feature two Stäubli robots, a TX2-60 HE and a Red Dot Award-winning TS2-60 HE, using conveyor tracking technology to cut and handle raw meat. The TX2 will use a waterjet cutter to simulate cutting the meat into portions and then placing them on a conveyor. When the camera detects them, the tracking application directs the TS2 to transport them into a packaging unit.

Another demo will show high-speed convenience food tracking with chicken. A TS2-80 HE robot will use its vision sensor, featuring a SensoPart camera, to accurately detect the products. It will then delicately yet securely grasp the chicken parts using a food-grade gripper from SoftGripping to fill containers quickly and precisely.

The robots’ ability to handle viscoelastic and fragile foods while maintaining the product’s shape and other properties proves their exceptional degree of control.

The show-stopping TX2-200 robot, newly modified for food production

Stäubli will also exhibit its TX2-200 HE, a powerful robot at the top of the TX2 HE portfolio, equipped with a meat processing tool. Launched in 2024, this higher-performing machine features:

Reliable support throughout the equipment lifecycle

Stäubli Robotics offers a wide variety of support and training options, including on-site repair services worldwide to resolve issues quickly and help customers maximize the availability and reliability of their robots. The result is a robot availability rate of 99.95%.

Customers can choose the right level of support for their specific needs. Three Care Packages—Care Compact, Care Plus, and Care Premium—provide flexible options such as robot health check-up visits, preventive maintenance visits, service warranties, and other perks. An after-sales hotline, D-day spare parts shipment, discounts, and more are included with all packages.

MyStäubli Portal, an enhanced online customer support platform, lets customers easily track service and maintenance and access an extensive technical library with CAD files and software, application support, and professional training with Robotics Academy.

Robust service, support, and training help customers safeguard their investment in addition to the efficiency, productivity, and quality gains they can expect. Stäubli robots are energy-efficient and have the best-in-class lifetime for robots used in harsh and sensitive environments such as food production. Their hygienic encapsulated design allows faster cleaning processes with no cover required. Oil changes are also quick with integrated Stäubli CBI fluid connectors.

IFFA attendees will not want to miss seeing Stäubli’s technology on display at Booth D31.

Stäubli is a global industrial and mechatronic solution provider with four dedicated Divisions: Electrical Connectors, Fluid Connectors, Robotics and Textile, serving customers who aim to increase their productivity in many industrial sectors. Stäubli currently operates in 28 countries, with agents in 50 countries on four continents. Its global workforce of 6,000 shares a commitment to partnering with customers in nearly every industry to provide comprehensive solutions with long-term support. Originally founded in 1892 as a small workshop in Horgen/Zurich, Switzerland, today Stäubli is an international Group headquartered in Pfäffikon, Switzerland.

https://www.staubli.com/global/en/home.html

About Stäubli Robotics

Stäubli Robotics’ unique product portfolio contains 4 and 6 axis industrial robots, cobots, mobile robotics and Automated Guided Vehicles. The powerful, high precision solutions allow clients in many demanding industries to tackle the challenges of Industry 4.0 under specific manufacturing conditions.

Robotic automation for industrial applications | Stäubli

https://www.linkedin.com/company/staubli-robotics/

Stäubli Tec-Systems GmbH Robotics

Theodor-Schmidt-Str. 19/25

95448 Bayreuth

Telefon: +49 (921) 883-0

Telefax: +49 (921) 883-3244

https://www.staubli.com/de/de/robotics.html

![]()