Optimizing Packaging Efficiency with Flexible Automation for Existing Lines

Breaking News:

Dienstag, Feb. 11, 2025

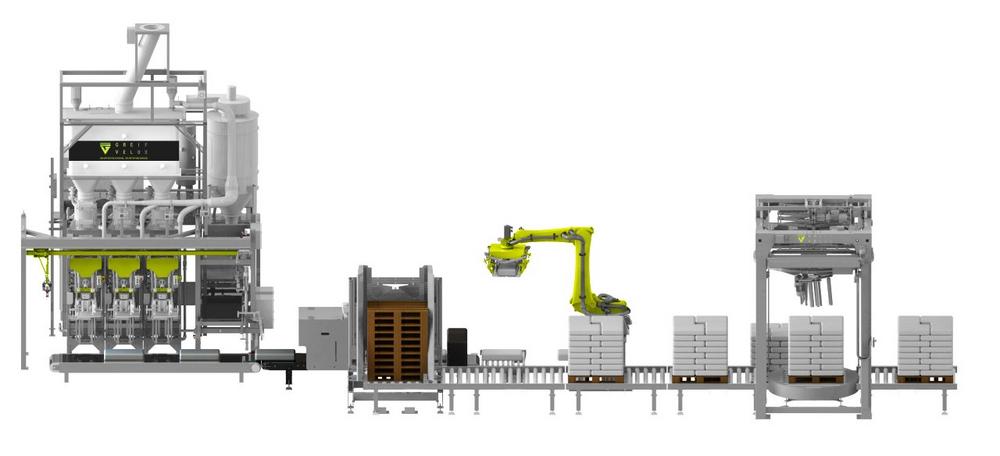

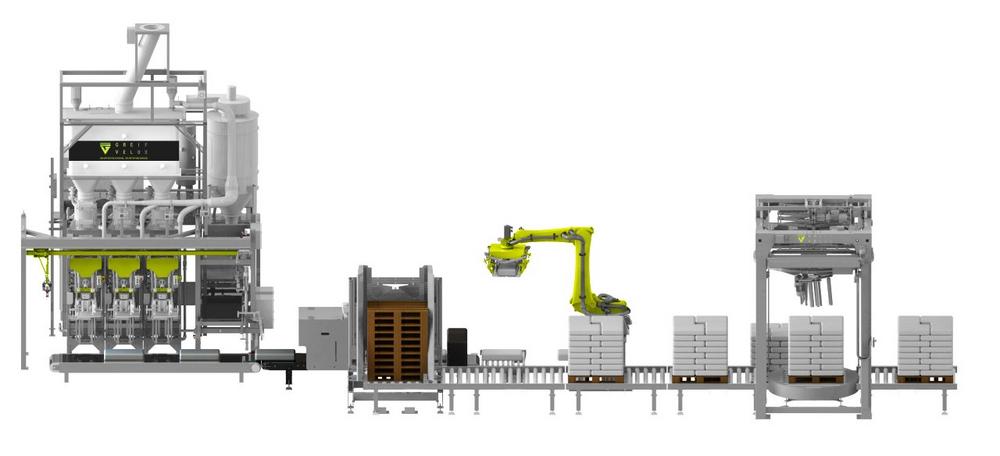

By utilizing the VeloPack robotic palletizer, the VeloFlexLabeler for robotic labeling, and automated load securing systems, Greif-Velox enhances packaging efficiency with its solutions, to help minimize manual intervention and downtime, improve workplace safety, and ensure optimized process flow. Thanks to their modular design, their systems can be easily integrated into existing packaging lines, thereby optimizing the handling of various packaging types—including bags, drums, canisters, hobbocks, cartons and roll goods.

Fully Automated Solutions for Palletizing, Labeling, and Load Securing Across Industries

With decades of experience in packaging automation, Greif-Velox provides comprehensive solutions for palletizing, labeling, and load securing to companies in the chemical, petrochemical, food, and building materials industries. These solutions include:

Maximum Efficiency Through Advanced Robotics

Thanks to a strategic partnership with KUKA, one of the world’s leading robotics manufacturers, Greif-Velox leverages cutting-edge robotics and automation technologies to make packaging processes more efficient, safer, and sustainable.

“Our fully automated solutions position Greif-Velox as a leader in packaging automation,” according to Sebastian Pohl, Managing Director of Greif-Velox. “Our robotic palletizers, automated labeling systems, and load securing solutions ensure consistently optimized processes—no matter whether they are utilized in new or existing facilities.”

Future-Proof Automation for Increased Productivity and Sustainability

With the growing pressure on companies to enhance efficiency, safety, and sustainability, automated packaging solutions provide a key competitive advantage.

“Greif-Velox focuses on scalable, intelligent automation concepts that help businesses future-proof their production environments while maximizing cost efficiency,” explains Sebastian Pohl. “We see ourselves as a partner for our customers, one who offers well-thought-out full-line concepts precisely tailored to their needs.”

Learn more about Load Securing: https://www.greif-velox.com/en/systems/load-securing

Learn more about Robot Palletizing: https://www.greif-velox.com/en/systems/robot-palletizing

For more information, visit https://www.greif-velox.com.

GREIF-VELOX Maschinenfabrik GmbH (https://www.greif-velox.com/en/) sets global benchmarks in packaging machinery and is on its way to becoming a technological leader in the industry. The company designs and implements innovative bagging machines and filling systems with a strong focus on maximizing customer efficiency. Among its breakthroughs, GREIF-VELOX has introduced the VeloVac gross vacuum packer, revolutionizing the packaging of ultra-light powders.

In addition to bagging technology, its portfolio includes palletizing robots, enabling complete full-line solutions. With its customer needs at the forefront, the company continuously develops new systems and patents that provide long-term solutions to industry challenges.

With a nearly 1,000-year corporate history, GREIF-VELOX has consistently demonstrated its three core values: Efficiency, Innovation, and Reliability (EIZ). Today, GREIF-VELOX Maschinenfabrik GmbH operates worldwide with more than 150 experts in 89 countries. Since 2024, Sebastian Pohl and Thorsten Köll have been appointed as managing directors. In 2025, GREIF-VELOX will celebrate its 80th anniversary at its Lübeck (Schleswig-Holstein, Germany) location.

GREIF-VELOX Maschinenfabrik GmbH

Kronsforder Landstr. 177

23560 Lübeck

Telefon: +49 (451) 5303-0

Telefax: +49 (451) 5303-233

https://www.greif-velox.com

![]()