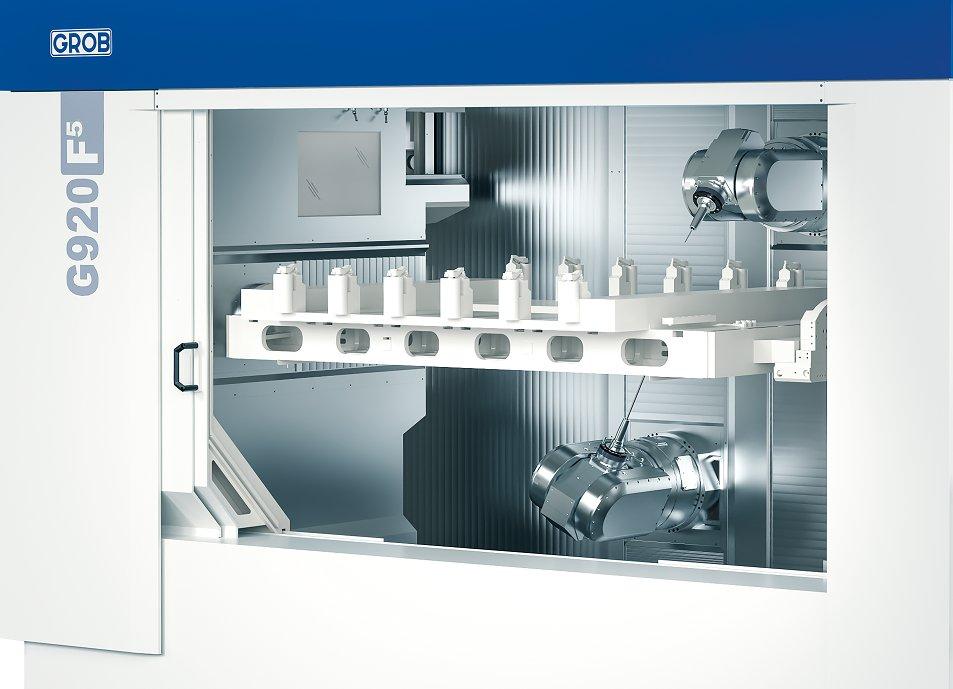

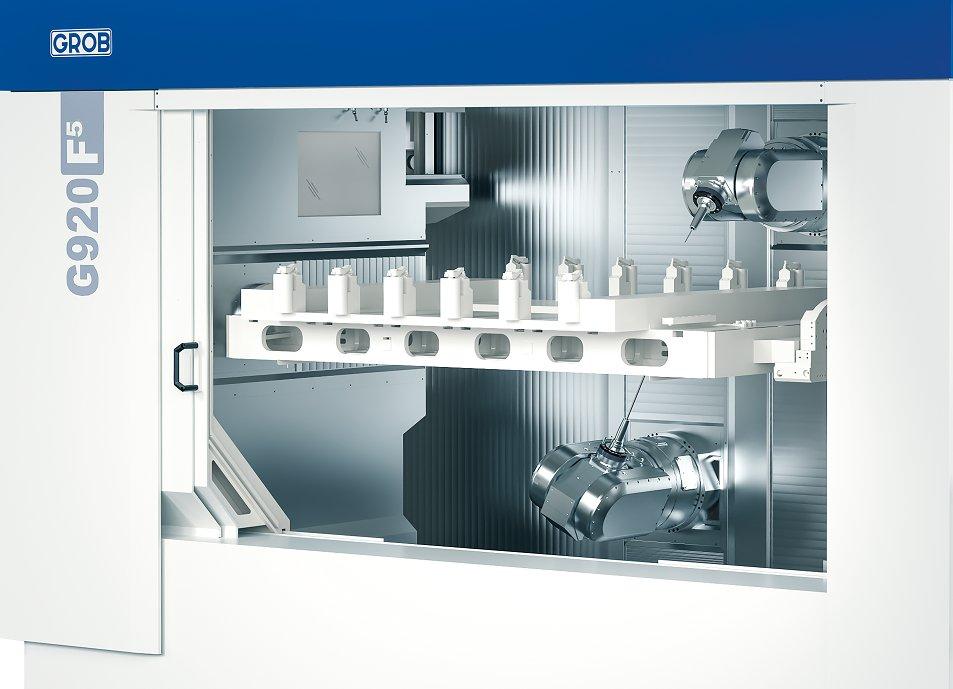

GROB presents the G920F5 machining center for mega and giga castings

"With the G920F5, we are setting new standards in machining technology and offering a future-proof solution for the automotive industry," explains Carsten König, Head of Machining Technology and Digital Products at GROB. "Our machine is not only robust and reliable, but also extremely flexible in its configuration, which makes it the perfect choice for the diverse requirements of modern vehicle production."

The G920F5: A milestone in machining technology

The G920F5 machining center has been specially developed for the task of machining so-called "giga-castings" – large-format components that are increasingly being used in the automotive industry. These components, often referred to as "underbodies", place high demands on the machines that process them. The G920F5 meets these requirements with its robust design and 5-axis machining capability, which enables precise and efficient tasks even under demanding conditions.

"The development of the G920F5 was an exciting challenge that we took on with great commitment," says König. "We wanted to create a machine that not only meets today’s requirements, but also those of the future." Since fall 2023, GROB has already sold this machine over 50 times around the globe, making the machine a success story. On the one hand as part of projects with existing customers, but also with new customers in Japan.

Innovation meets flexibility

The G920F5 is not only optimized for the task of giga-casting, but also offers a high degree of flexibility thanks to its modular design and diverse automation options. This makes it the ideal solution for the production of a wide variety of component designs. From frame structure parts to battery housings – the G920F5 is suitable for a wide range of applications and enables efficient and resource-saving production. "Our close cooperation with OEMs and suppliers to the automotive industry has enabled us to tailor the G920F5 precisely to the needs of the industry," emphasizes König. "The machine is a real all-rounder and offers enormous added value for our customers thanks to its adaptability."

In addition to the G920F5, GROB also offers other machines in the G900 series, including the G920X for the task of extruding profiles and the G920F4 for the complete machining of battery housings. All machines in the series are designed for maximum performance and precision and offer solutions for the growing challenges in the automotive industry. "With the G900 series, we have created a machine platform that is unrivaled in the industry," says König. "Our machines are designed to meet the increasing demands of the automotive industry while offering maximum efficiency and sustainability."

Customized solutions for the task of extruding profiles

The G920X was specially developed for the demanding task of extruding profiles. The machine has two spindles and bridges arranged one above the other, enabling the simultaneous processing of two parts. "With a processing length of over 2.5 meters, the G920X is particularly suitable for the machining of aluminium profiles , which are often used in car body construction and crash management systems," explains König. "Thanks to its robust and rigid design, the G920X guarantees high stability and precision, even under the toughest conditions." The machine is characterized by its high flexibility, which enables customers to efficiently task a wide range of profile geometries. Thanks to its modular design and the possibility of automation, the G920X offers an optimal solution for companies that require both precision and high throughput rates.

The ideal choice for the complete machining of battery housings

The G920F4 is the ideal machining center for the complete machining of battery housings and their components. This machine was developed to cover the entire machining process of large parts while ensuring high productivity. "With two optional spindles arranged side by side or one above the other and a table on which workpieces up to a length of 3,000 mm can be machined, the G920F4 offers maximum flexibility," emphasizes König. The G920F4 enables efficient 4-axis machining and impresses with extremely short chip-to-chip times and high dynamics. "Our customers benefit from the high production flexibility of the G920F4, which impresses with its modular design, changeover capability and the possibility of automation systems," König continues. The particularly rigid construction and the machine design tailored to minimum quantity lubrication (MQL) ensure an optimal workspace design and a large chip hopper for efficient chip removal.

Pioneering technologies for the automotive industry

With the new G900 series, GROB is once again underlining its leading position in the mechanical engineering industry. The machines are specially tailored to the requirements of modern automotive production and offer future-proof solutions for the task of mega and giga-castings as well as extruded profiles.

Visitors to this year’s in-house exhibition will have the opportunity to experience the G920F5 live and see its unique performance features for themselves. "We are looking forward to presenting the benefits of our latest machine series to our customers and shaping the future of machining technology together," concludes König.

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

![]()