Precision and Reliability in Surface Measurement

Breaking News:

Freitag, Dez. 19, 2025

Precision in Roughness Measurement

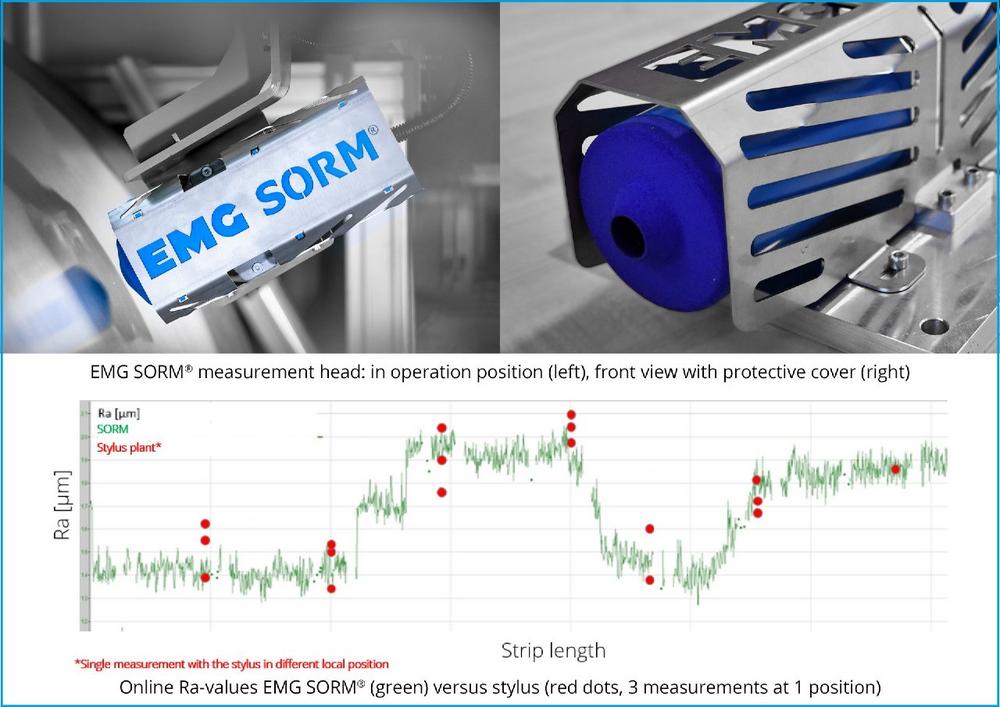

Surface roughness is a critical quality parameter in cold-rolled steel and aluminium production, particularly in automotive and high-quality grade manufacturing. The EMG SORM® system determines roughness parameters such as Ra (arithmetic mean roughness) and RPc (peak count) with a high level of accuracy.

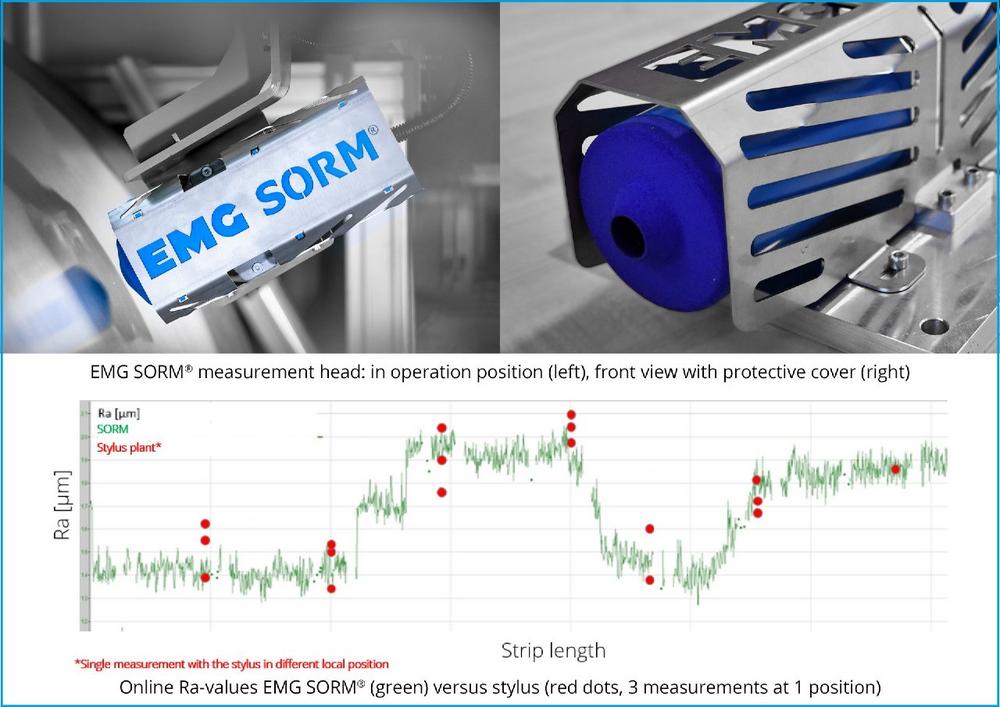

To validate the system’s accuracy, a comparison was conducted between EMG SORM® online measurements and traditional stylus-based methods. In tests conducted on a continuous galvanizing line (CGL), results from 858 coils were analysed. The findings demonstrated:

Additionally, the system successfully detected variations in roughness resulting from changes in rolling forces along the strip length (see bottom part of the illustration). This capability ensures real-time monitoring of process influences on surface texture, allowing for immediate corrective actions. The ability to capture fluctuations continuously rather than relying on isolated sample measurements gives EMG SORM® a significant advantage over traditional methods.

Accurate Waviness Measurement for Enhanced Product Quality

Waviness, often overlooked in conventional quality control, can lead to serious issues in coating adhesion, paint finish uniformity, and structural integrity. The EMG SORM® system addresses this challenge by providing continuous, high-resolution waviness measurements (Wsa parameter).

A comparative study between EMG SORM® and a stylus instrument (Hommel T8000) was conducted on 80 samples from a continuous annealing line. The results showed:

Unlike conventional tactile measurement that rely on sample-based evaluations, EMG SORM® enables in-line monitoring, ensuring that surface waviness is controlled throughout the production process and, if required, in a traversing mode across the width of the strip. This is particularly important for production lines where visual quality and coating adhesion are key factors, such as automotive grade manufacturing and house-hold appliance production.

Key Technical Data of EMG SORM®

To fully understand the capabilities of the EMG SORM® system, you’ll find its main technical specifications below:

Key Takeaways from EMG SORM® Roughness and Waviness Measurement

The introduction of EMG SORM® has set a new standard in online surface quality measurement. The integration of roughness and waviness measurement in a single sensor significantly simplifies the monitoring process while improving accuracy and response time. The system has proven:

The combination of these capabilities makes EMG SORM® an essential tool for quality management in flat steel and aluminium and metal finishing applications. As the demand for high-quality flat products continues to rise, having a robust, in-line monitoring system ensures manufacturers can meet strict industry standards without compromising efficiency.

For support or further details on how the EMG SORM® system can enhance your production processes, contact EMG Automation GmbH, visit our website at www.emg.elexis.group/en/, or reach out to our product manager, Franziska Kneisel (franziska.kneisel@emg-automation.com).

For a visual impression of EMG SORM® don’t miss the short product film @YouTube.

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

![]()