TÜV SÜD drives innovations in HV component testing for electric vehicles

Electric vehicles (EVs) are based on advanced high-voltage systems that can reach up to 1,500 volts. These technologies demand rigorous standards of safety and efficiency. As a strategic partner to the automotive industry, TÜV SÜD oversees the compliance of high-voltage components with the strict specifications set out in the applicable standards. The company offers a safe, accurate, and efficient solution that ensures components meet the requirements imposed by their operating environments – such as low temperatures, vibration, and corrosion – and fulfill electromagnetic compatibility specifications.

Focus on high-voltage testing

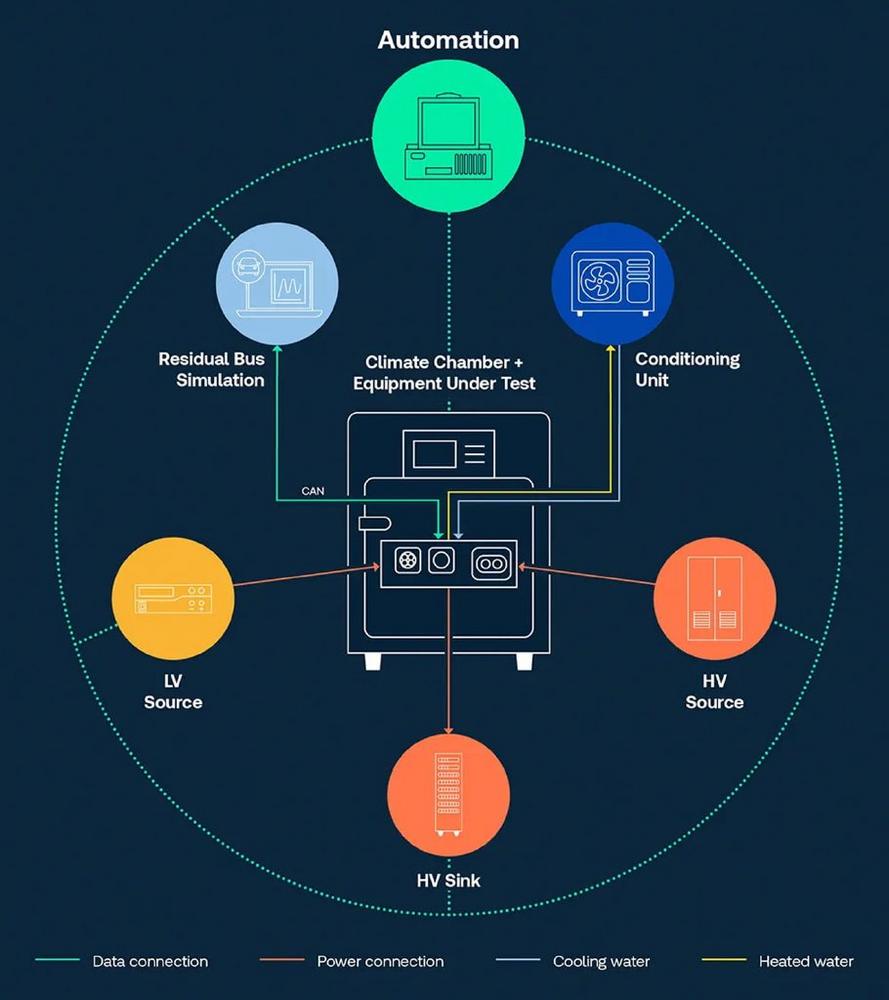

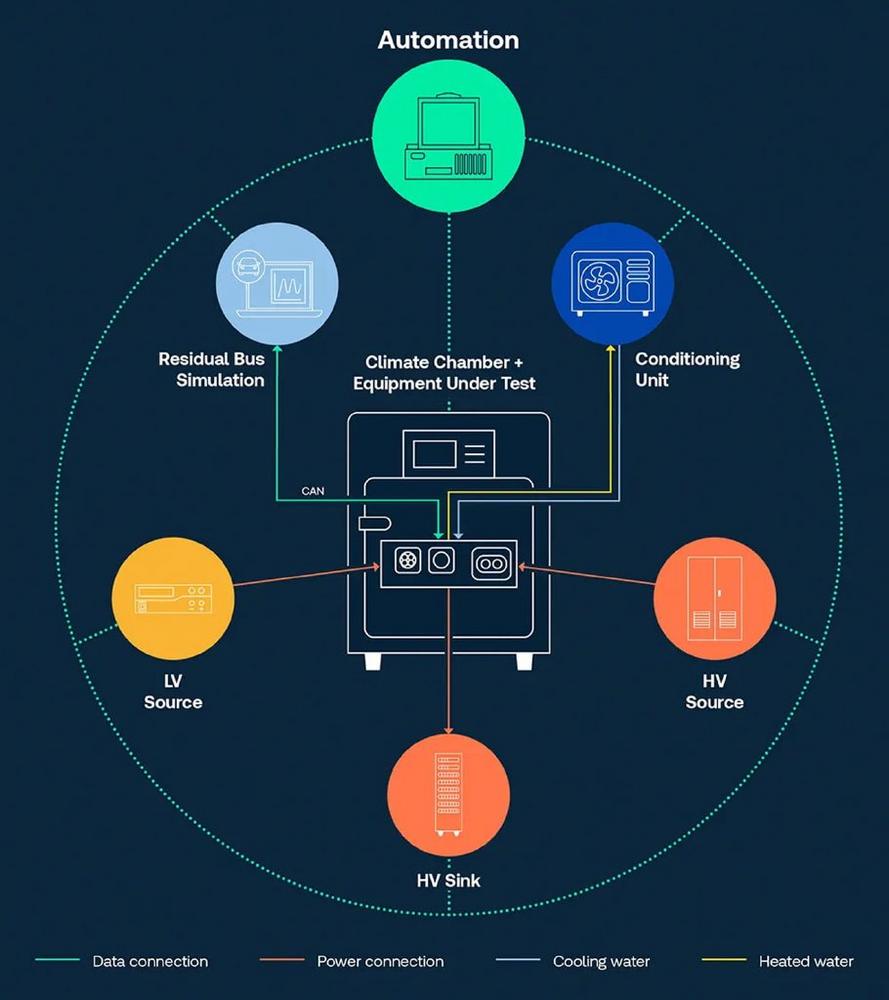

The HV testing scheme comprises testing of HV components under simulated environmental conditions in accordance with standards including LV123, LV124, LV148, and further customer-specific standards. The tests provide proof that the high-voltage components are able to function efficiently and comply with ultra-strict safety requirements. They include:

“Electric vehicles need to be energy-efficient as well as extremely safe, particularly where their high-voltage components are concerned,” explains Benjamin Sommer, Senior Account Manager TÜV SÜD. “At our testing facilities, we guarantee that HV components such as on-board chargers, inverters, and e-motors comply with strict functionality and safety specifications under even the most extreme conditions. With the advantages of our years of experience and state-of-the-art equipment, we can address individual needs and contribute to the development of high-quality and safe products.”

TÜV SÜD’s ultra-modern test beds and testing methods deliver precise analysis of the behavior of EV components under extreme ambient conditions that extend beyond standard requirements. Understanding of the failure mechanism in the event of damage is a crucial aspect in the development of HV components.

Innovation driver in electric vehicles

As a pioneer in electromobility, TÜV SÜD is committed to the ongoing pursuit of innovation and development of testing methods. The company’s wealth of expertise and modern testing facilities enable it to go above and beyond standard testing and supply tailored testing schemes reflecting cutting-edge developments in EV technology.

TÜV SÜD uses digital tools and connected testing methods to continuously optimize its testing processes. Tests are monitored and analyzed in real time using integrated data analysis and evaluation tools. As well as reducing testing time, this allows manufacturers to respond more rapidly to technical challenges and speed the time to market of their innovative products.

“At TÜV SÜD, we view our role as a provider of future-facing testing, inspection, and certification services to industry,” explains Sommer. “By developing new testing processes, we aim to continuously improve the safety and performance of electric vehicles and accelerate the introduction of innovative technologies.”

Global testing services

Customers of TÜV SÜD enjoy the benefits of the company’s global presence, with testing facilities in all of the major automotive markets. By working closely with global manufacturers and suppliers, TÜV SÜD guarantees that its testing programs comply with both locally applicable regulations and the strict requirements of international markets.

TÜV SÜD’s HV testing laboratories are accredited to the latest international standards and provide an ideal environment for advanced testing series. The company supports the automotive industry in ensuring that all high-voltage components, from batteries and inverters to power electronics, meet the highest standards of safety and performance.

Further information: tuvsud.com/en/resource-centre/stories/high-voltage-testing

Founded in 1866 as a steam boiler inspection association, the TÜV SÜD Group has evolved into a global enterprise. About 28,000 employees work at over 1.000 locations in about 50 countries to continually improve technology, systems and expertise. They contribute significantly to making technical innovations such as Industry 4.0, autonomous driving and renewable energy safe and reliable. tuvsud.com

TÜV SÜD AG

Westendstraße 199

80686 München

Telefon: +49 (89) 5791-0

Telefax: +49 (89) 5791-1551

http://www.tuvsud.com/de

![]()